This will help us understand how disconnections are nucleated, interacting with regular lattice dislocations, and need or not diffusion (nucleation/absorption at triple junctions).

We will then combine in situ TEM, SEM and STM/AFM experiments on nc-and UFG Ni and Al that have very different melting temperature. On the same bicrystals, Scanning Tunneling/Atomic Force Microscopy (STM/AFM) tests will also be performed to apprehend the third dimension of plastic deformation that is often hard to measure in TEM and to complement TEM observations of events occurring in a truly bulk metal. High Resolution Transmission Electron Microscopy (HRTEM) will be used to analyze the defects involved at the same scale than the simulations. We will work on defined Al bi-crystals where the shear-coupling mechanism involved in GB migration is both easier to study experimentally and to confront to molecular dynamics models that are also bi-crystalline for the moment. The goal of this project is to make some significant progress on the fundamental understanding of disconnection-based GB mechanisms, both at the atomic, nanometer and micrometer scales.

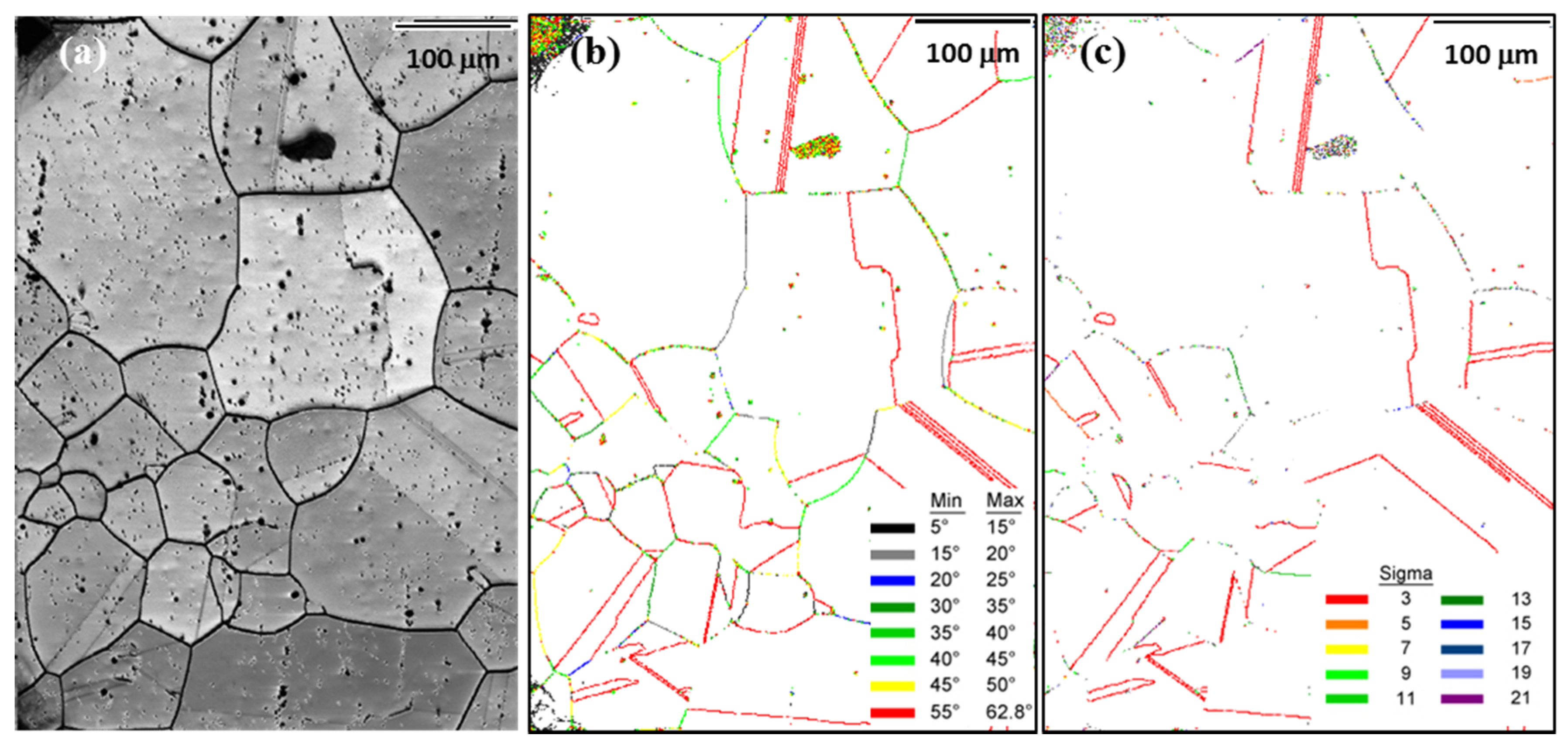

The gap between theoretical studies, often considering GBs as flat and perfect objects, and experiments that try to have statistical overviews of large ensemble of GBs is also considerable today. Indeed, GBs are complex objects with more degrees of freedom than crystals and they virtually contain an infinity of different disconnections. This concept extend to GBs the current understanding of mechanical properties of crystal dictated by their dislocations.ĭespite this potentially important implication in many fields of metallurgy and materials science, GB-based plasticity is very poorly known today. Hence we have started to infer that a paradigm shift should be made: GBs are not simply defects of an hypothetical single crystal, but form networks of their own, which mechanical properties depend on their own defects (the disconnections). We also showed that many types of disconnections can be found in a single GB, and that most of the GB-based plasticity mechanisms may be explained using this single type of defect. These defects, specific to GBs, possess a Burgers vector (as a dislocation) and a step character. By coupling molecular dynamic simulations and in situ electron microscopy, we recently showed that this mechanism is heavily dependent on GB-specific defects called "disconnections", or step-dislocations. Among them, the shear-coupling grain boundary migration drew a great interest in the last 10 years or so for its potential effectiveness. This generic term regroups several mechanisms (GB sliding, grain rotation, enhanced diffusion, etc…). Remarkably, the plasticity of these materials seems to rely significantly on GB-based mechanisms. A considerable amount of studies have tried to understand the plastic deformation of these classes of materials. Recent years have seen the emergence of ultra-fine grained (grain size below 1 µm) or nanocrystalline (nc-, grain size below 100 nm) materials, where dislocation-mediated plasticity was reduced or even shut down. In studies about the deformation of polycrystalline solids, GBs are usually considered as static, obstacles for dislocations that are the main vector of plasticity. They are found in most of the metals, alloys, ceramic materials, and more generally in any crystalline solid. Grain boundaries (GBs) are the defects that separate two domains possessing different crystallographic orientations (commonly called "grains"). This research proposal aims at understanding the ROle of DIscoNnections in grain-boundary-based plasticity (RODIN).

0 kommentar(er)

0 kommentar(er)